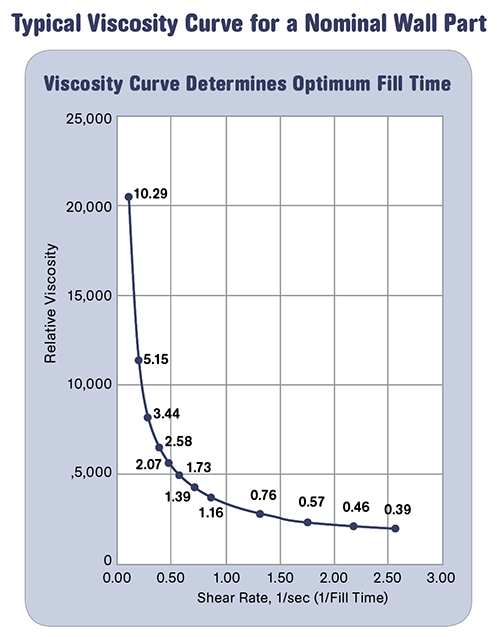

The higher the viscosity, the more friction that exists, so the more pressure you need to inject it into a mold. Viscosity is a fluid’s resistance to flow, or the amount of friction that exists in the material. This article covers the definition and characteristics of viscosity, why it’s important to monitor viscosity, and how to measure viscosity. If, by the student’s estimation, 90% of our issues come back to viscosity, it sure would make sense to track it. If the viscosity of the material was either consistent or predictable, this whole injection molding thing would be easy. We like asking why things happen, and quite often viscosity is indeed the answer. Careers We’re hiring! Check out our open positions.Ī student once joked that, “9 out of 10 times when you ask a question, the answer is viscosity.” While it’s probably not quite 9 out of 10, the student did have a point.Mold Smart Award Apply for our annual RJG Mold Smart Award.Partners Meet our awesome partners who allow us to do what we do.Testimonials Hear what our clients have to say about working with us.Consultant Trainers Meet our expert consultant trainers.About Learn more about who we are, what we do, and why we do it.Newsletter Receive the latest in news and information from RJG.Art’s Tips Art Schubert, RJG Chief Engineer (1989-2016), helped molders avoid common pitfalls.Knowledge Base Find answers to common RJG related questions.Whitepapers Gain knowledge on various injection molding topics.Webinars Watch informational webinars presented by our industry experts.Product Docs Download all of the information you need for each of our products.Blog Learn injection molding tips, how-to’s, and industry trends.Contact Support Have a general question, want to request an RMA, or need assistance with sensor selection or placement? We’re here for you.

0 kommentar(er)

0 kommentar(er)